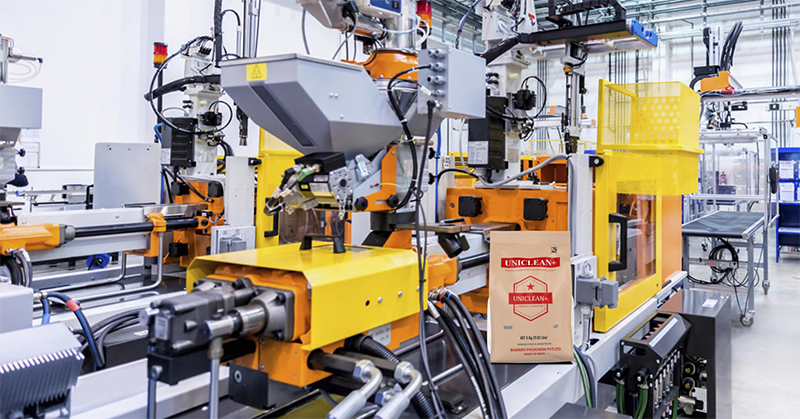

Purging Compound for Injection Molding

Purging a plastic injection molding machine with resin for color changes or carbon removals usually leads to expensive waste & loss of production time. Apart from choosing the right purging compound for injection molding, there’re a few best practices and procedures your business should follow to make sure the purging process is fast & thorough.

Our high-quality purging compound are ready-to-use, pre-mixed compound that can be successfully used in the injection molding process for getting rid of

- Burned streaks

- Foreign contaminants

- Un-melted resins

- Tarnished leftovers from the machine barrel.

Injection molders can harvest many benefits after a purge, including lesser scrap parts, fewer carbon accumulation in the barrel, exclusion of colour hanging up in the tool, and a drop in colour changing time & overall changeover time. The downtime is also significantly decreased.

Purging Instructions For Plastic Injection Molding Machine:

- Ensure that all zones are in the correct temperature range for the grade of UNICLEANPLUS purging compound being used.

- Pull back the injection unit. Unfilled screw & barrel. Clean hopper & feed throat.

- Feed 1-2 barrel capacities of UNICLEANPLUS purging compound into the feed throat.

- With the screw totally forward, increase the backpressure to the highest level.

- Once UNICLEANPLUS purging compound starts to come through the nozzle, accelerate the screw speed to the highest safe level.

- Reduce the backpressure once the purging compound coming from the nozzle is nearly clean.

- Pull back the screw and execute short, preferablyhigh-speed injection shots.

- Repeat step number 3-7 if pollutants are still detectible.

- Purging compound remaining in the machine gets dislocated with the next resin.

So you have decided to use UNICLEANPLUS Purging Material for Injection Moulding! Feel free to schedule a free consultation with one of our purging compound experts!

Need trial sample?

We are here to Help. Learn more about the benefits of UNICLEANPLUS™ purging compounds.