Reasons Why You Should Use UNICLEANPLUS™ Purging Material

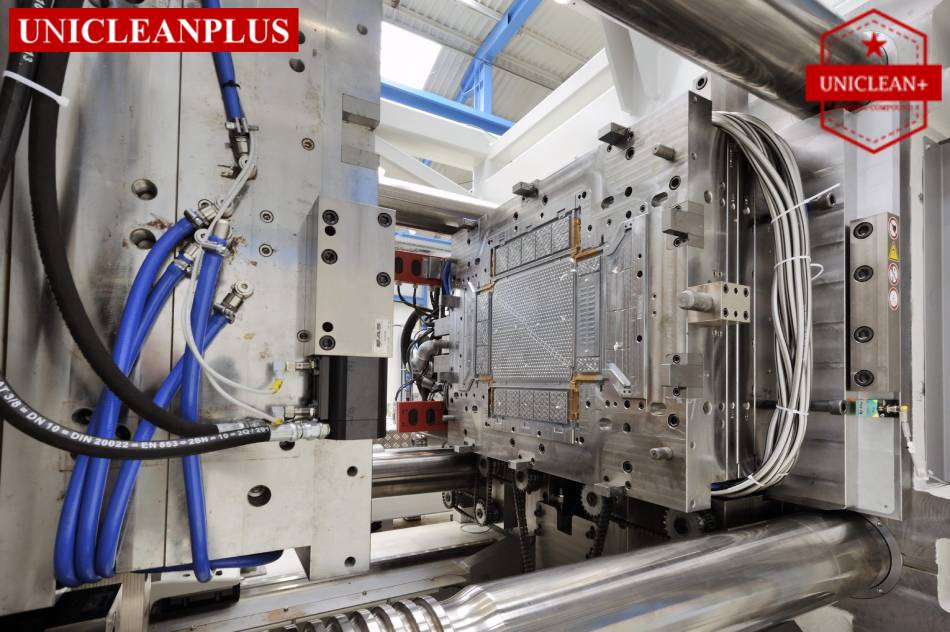

How do injection moulding machine owners and extruders of thermoplastic producers clean their machines? They use the products called Purging Materials and Purging Compounds in the machine cleaning process. It will remove the residues of screws, nozzles, mould, hot runners. We offer our clients our innovative UNICLEANPLUS™ Purging Material for Injection Molding. It can lower …

Reasons Why You Should Use UNICLEANPLUS™ Purging Material Read More »