Purging Compound

UNICLEANPLUS™- Leading Purging Compound Supplier

UNICLEANPLUS™ is a highly reliable and leading purging compounds supplier that provides highly effective purging solutions for various applications. Our highly efficient purging compounds are developed to cover a wide array of operating temperatures, equipment types, and process applications. At UNICLEANPLUS™, we provide the highest quality purging material to address the challenges of the thermoplastic processors that enhance their performance and operations.

Purging compounds are essential for maintaining the efficiency and longevity of your equipment. Our purging compounds are specially formulated to clean extruders, injection molding machines, and blow molding machines. By using UNICLEANPLUS™ purging compounds, you can significantly reduce downtime and material waste, ensuring a smoother production process.

Highly Efficient Purging Compound for Plastic

Purging compounds play an essential role in modern thermoplastic processors. Our purging compound for plastic is designed for parameters and operational processes to provide a competitive advantage. Whether it is about eliminating carbon buildup in barrel assemblies or screws, our purging material proves to be efficient enough!

As a reliable purging compound supplier, we have a significant impact on lowering the scrap rates, improving processing efficiency, and assuring the right equipment maintenance. With our purging products, you can experience a reduction in polymer change time or reductions in material consumption while color changeovers, that enhance operational margins. Our purging products can help you experience an increase in labor and equipment uptime that allows your organizational assets fully leveraged and enhances the manufacturing process.

What Is a Purging Compound?

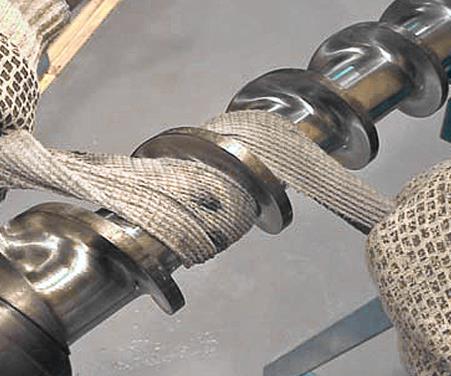

A purging compound is a specially formulated material used in the thermoplastics industry to clean screws, barrels, nozzles, dies, and hot runners in injection molding machines and extruders. Unlike traditional virgin resin cleaning, this cleaning agent significantly reduces machine downtime and scrap generation during material or color changes.

Why Use a Purging Compound for Plastic?

Using a purging material designed for plastics ensures faster and more effective cleaning. These compounds are formulated with agents such as emulsifiers, foaming elements, and mild abrasives that help remove contamination from machinery. Unlike molding-grade resins, which aren’t meant for cleaning, these materials are specifically developed for system flushing.

Key Benefits of Using Purging Compounds:

-

Reduces Scrap: Effectively clears residue and leftover color from previous production runs, minimizing waste.

-

Minimizes Downtime: Helps speed up resin and color changeovers, saving valuable production time.

-

Removes Contaminants: Breaks down carbon deposits, gels, and streaks, reducing part rejection and avoiding unexpected production halts.

-

Prevents Screw Pulls: Regular cleaning reduces the need for manual screw removal and internal cleaning.

-

Cleans Hot Runners: Specially formulated unfilled compounds are safe for use through molds and effective for cleaning stubborn color residues in hot runners.

-

Lowers Rejection Rates: Proper cleaning after material changes or shutdowns results in consistent quality and fewer rejected parts.

-

Cost-Efficient: While evaluating the investment, consider not only the price of the compound but also savings in labor, material waste, machine time, and customer satisfaction.

Types of Purging Compounds

There are several types of purging materials available to meet different manufacturing needs:

1. Mechanical Purging Compounds

These rely on physical force to remove contaminants and are typically pellet-based. They combine base resins with low melt flow indices and additives for effective scrubbing.

2. Liquid Purging Compounds

These chemically active liquids induce flow instability and penetrate hard-to-reach zones inside the barrel. They’re highly concentrated and used in small quantities for efficient contamination removal.

3. Chemical Purging Compounds

Designed for deep cleaning, these require a short soak period (5 to 30 minutes) and operate through internal chemical reactions. They are available in various grades and are among the more premium options.

UNICLEANPLUS™ — Your Trusted Purging Solution Partner

At UNICLEANPLUS™, we are committed to supporting the thermoplastics industry with premium-grade purging materials developed for consistency, speed, and quality. Our advanced formulas are designed for injection molding, extrusion, and blow molding applications.

What Sets Our Products Apart?

Our uniquely developed purging materials outperform traditional cleaning methods by:

-

Reducing waste and scrap

-

Minimizing downtime

-

Ensuring smoother changeovers

-

Delivering safe, non-toxic, and non-abrasive cleaning

They are easy to use and compatible with a wide range of machines and temperature profiles—allowing seamless transitions between materials and colors without the hassle of manual temperature adjustment.

For manufacturers, every minute and every material count. Avoid unnecessary part rejections and operational delays by using our efficient cleaning solutions tailored to modern thermoplastic processes.

Let’s Help You Maximize Your Production Efficiency

UNICLEANPLUS™ is here to provide you with the best purging solution for plastic processing. Let our expert team guide you in selecting the right formula for your specific manufacturing needs.

Contact us today for expert advice and product recommendations!

Purging Compound FAQs

What do we understand by a purging compound?

Purging compounds are specific cleaning materials used to clean and wash out the interior of various processing equipment, such as machines for injection molding, extruders, and other plastic-making machinery, to eliminate residue and contaminants.

What is the working nature of UNICLEANPLUS’s purging compound?

There is the use of advanced formulations making it possible for UNICLEANPLUS’s purging compound to eliminate any build-up of polymer and contaminants from the equipment. This cleaning process makes certain that one can have a smooth transition between various materials and reduces downtime.

What are the types of machinery benefiting from the use of UNICLEANPLUS’s purging compound?

It is possible to use our purging material in various types of machinery, like injection molding, extruders and equipment for blow molding along with various other types of equipment.

How often should one use a purging material?

The interval between the uses of purging compound depends on the nature of your production and the change of materials. It is wise to use a purging compound when you change material and colours. It is also necessary to use these cleaning materials if you notice a decrease in production quality.

Is it safe to use UNICLEANPLUS’s purging material?

Without any doubt, we can say that it is safe to use our purging material as we formulate it to be safe for use. However, it is always good to follow the instructions and safety guidelines that we offer. This will ensure proper handling and use.

Is it possible to use UNICLEANPLUS’s purging material for both plastic and metal equipment?

We design our purging material for plastic processing equipment. If you need to use our purging compound for metal equipment do contact us and follow the manufacturer’s guidelines.

How can one apply UNICLEANPLUS’s purging material?

With every purging compound that we supply we offer certain instructions which you need to follow. Typically, the process involves adding the material, running it through the equipment and then cleaning any remaining residue.

Is it possible to enhance production efficiency using UNICLEANPLUS’s purging compound?

It is possible to enhance production efficiency using our purging materials. You can reduce downtime, and material waste and improve the quality of the final product.

What is the ideal way to store UNICLEANPLUS’s purging material?

While storing the material you need to ensure that it is not exposed to direct sunlight and extreme temperatures. You also need to ensure that the bag is tightly sealed to prevent contamination.

Where can I purchase UNICLEANPLUS’s purging compound?

You can purchase our purging materials from our authorised dealers or directly contacting us. You can contact us to gather more information on buying and the distribution process.

Need trial sample?

We are here to Help. Learn more about the benefits of UNICLEANPLUS™ purging compounds.