Purging Compound for Thermoplastics

IMPROVE EFFICIENCY, PRODUCTIVITY, SAVE TIME AND MONEY

UNICLEANPLUS™ is one of the leading partner in the world for purging compounds. Using a customer-centric approach, deep research and development, we collaborate with our customers to solve their challenge

Purging Compound for Thermoplastics

High-performance purging compounds for clean, efficient and safe processing

UNICLEANPLUS™ products are highly efficient purging compound developed to match various materials, machines, and operating ranges of plastics process producing a wide range of end products. We work closely with major plastic resin, colorant, and machinery producers around the world, while continually evolving our products to create the most effective purging compounds available to meet the unique needs of each customer..

APPLICATIONS

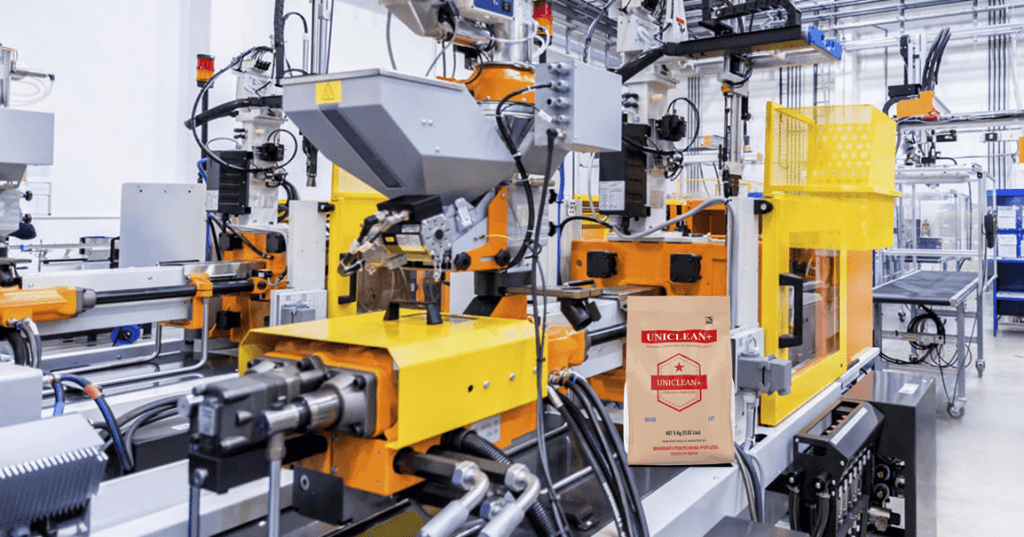

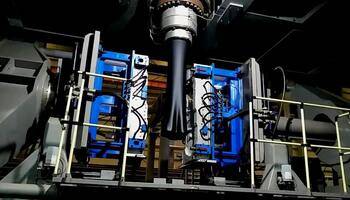

Injection Molding

Material changeover or carbon contamination removal from injection molding machine screw barrel could be inefficient & results in loss of productivity time while purging with polymer resins or regrind material.

UNICLEANPLUS™ offers broad range of highly efficient purging grades that can quickly clean wide range of polymer resins along with best purging procedure.

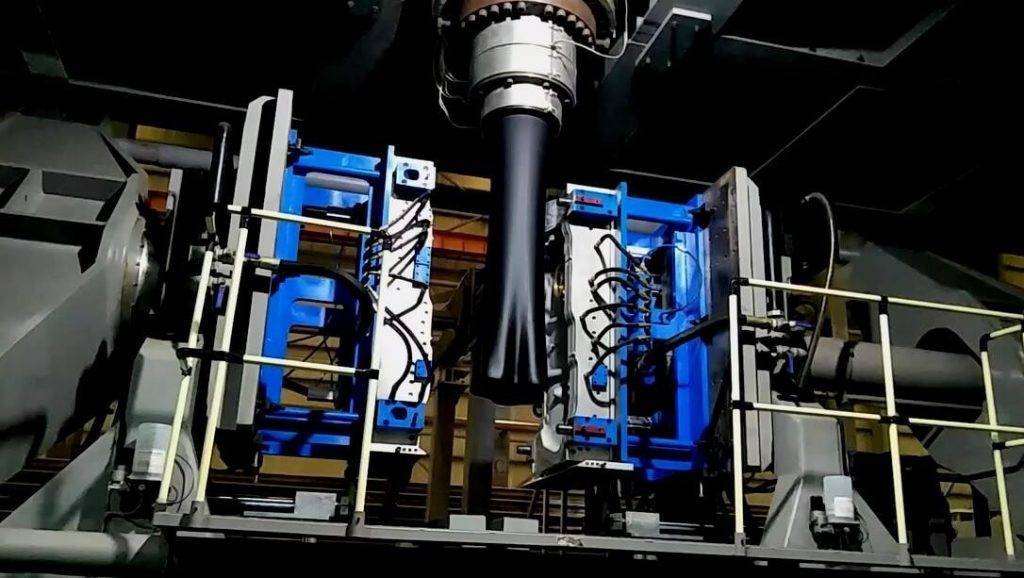

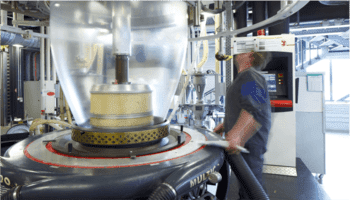

Blow Molding

Material changeover is one of the expensive problem faced in extrusion blow molding process. Purging with general resins will result in inefficient cleaning, huge quantity consumption and time loss.

UNICLEANPLUS™ offers grades that can quickly clean screw, barrel and die in extrusion blow molding.

Compounds in granule form & emulsion can be selected based on the machine specification and polymer used

We recommend to contact our expert for grade selection & trial support.

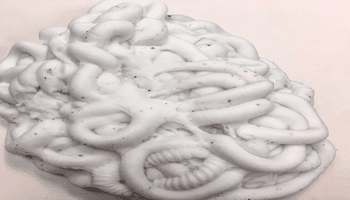

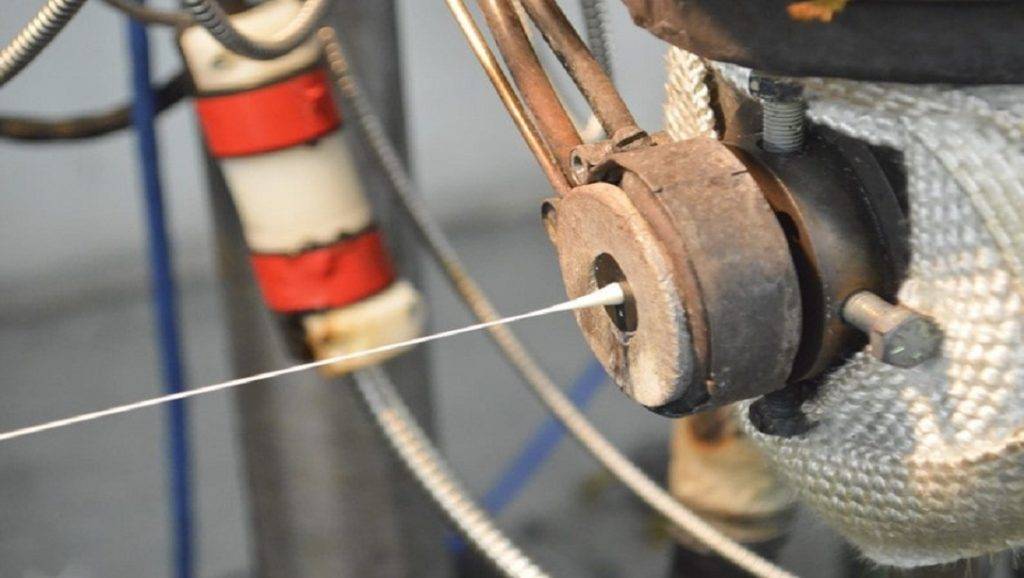

Extrusion

The extrusion process being a continuous process. Regular purging of thermoplastic extruders with UNICLEANPLUS™ compounds avoids product rejection, unexpected breakdowns and downtime. Applications includes wire extrusion, pipe extrusion, sheet extrusion, extruders for plastic compounding applications, blown film extrusion.

Contact us for expert advice & grade selection.

Request FREE trial sample

Why Choose Us

We believe that UNICLEANPLUS™ customers deserve the full benefit of every advantage our enterprise can offer. After all, our success is defined by our customers’ success. And with our rich experience in advanced thermoplastics applications we intended to serve you better.

Effective

High Cleaning power of UNICLEANPLUS™ guarantees faster material and color change and reduces molding material loss.

Safe

Non-toxic and non-abrasive on machine & mold elements

Economical

Reduces loss of molding material. Removes contamination in screw and barrel, thus reducing rejection rate. Leaves less residue in molding machine due to unique formulation.

Reduced Downtime

UNICLEANPLUS™ removes scaling formation, helps in avoiding tedious screw pulling exercise and downtime

Easy Use

Pallet form & emulsion forms for ease of handling and broad operating ranges that permits cleaning with no adjustment of barrel temperatures.

Reduced Scrap Rate

UNICLEANPLUS™ provides Lower number of rejects, less scrap and also prevent process challenges.

Need trial sample?

We are here to Help. Learn more about the benefits of UNICLEANPLUS™ purging compounds.